低烟无卤阻燃料

Low Smoke Zero Halogen (LSZH) Flame Retardant Polyolefin(FRPO) for Cable sheath

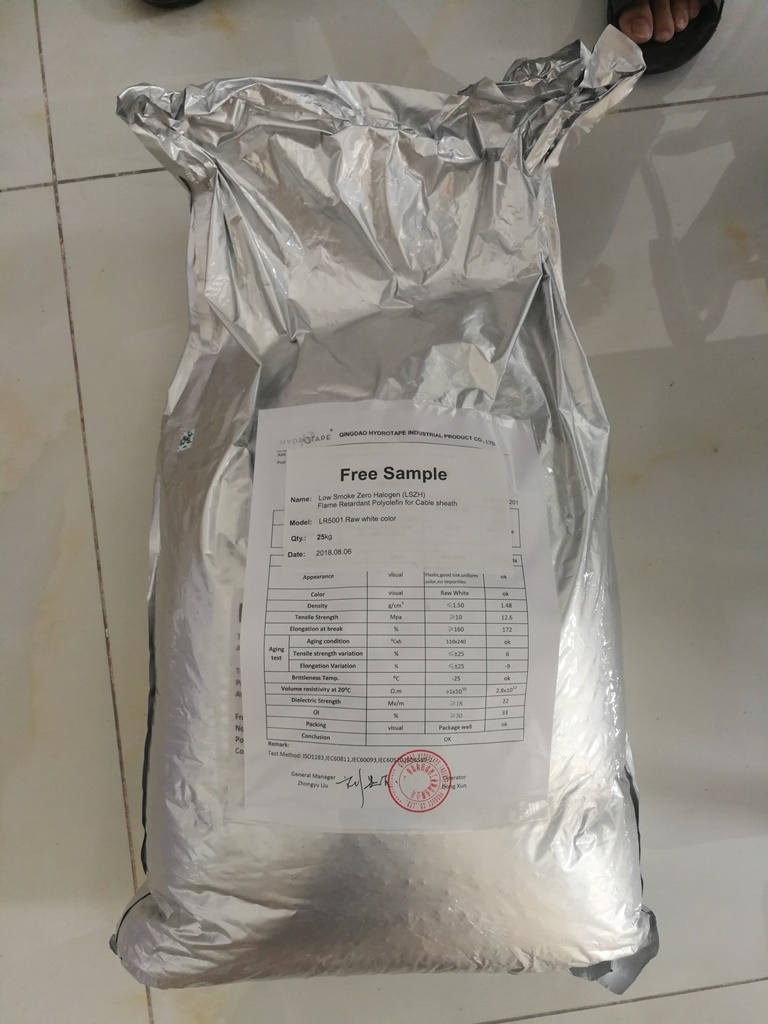

we can supply LSZH FRPO Cable compound LR5001 and LR5002 Series , it is Is it suitable for insulation (tight or buffer) of optical cables.

we have various of types with our customer's details inquiry, such as tigh or buffer, High speed(300m/min) or normal speed, ointment(GEL) resistant or not, 5G optical cable, Etc.,

Specification

LR-5001 LSZH FRPO

No. | Items | Unit | Test Methods | Typical value | ||

5001 | 5001-1 | 5001-P | ||||

1 | Density | g/cm3 | GB/T1033.1 | 1.49 | 1.48 | 1.50 |

2 | Tensile Strength | MPa | GB1040 | 12.2 | 12.1 | 11.4 |

Elongation at break | % |

| 159 | 168 | 155 | |

3 | Air heat aging | ℃×h | GB/T2951.2 | 100×168 | ||

Tensile strength retention | % | GB/T2951.1 | 108 | 108 | 110 | |

Elongation at break retention | % | 83 | 83 | 82 | ||

4 | Resistant to environmental stress cracking | F0--H | GB/T2951 | 180 | 180 | 155 |

One | 0 | 0 | 0 | |||

5 | High temperature thermal deformation(90℃*1kg) | % | GB/T8815 | 12 | 12 | 13 |

6 | Low-temperature impact embrittlement(-40℃) |

| GB/T5470 | 0/30 | 0/30 | 0/30 |

7 | Oxygen Index | % | GB/T2406 | 33 | 34 | 30 |

8 | Smoke density | Flameless method | GB/T8323 | 240 | 240 | 295 |

9 | Halogen acid gas content | mg/g | GB/T17650.1 | 0.2 | 0.1 | 2.0 |

10 | PH value |

| GB/T17650.2/ | 5.3 | 5.5 | 4.9 |

| Conductivity | μs/mm | 0.95 | 0.70 | 1.5 | |

11 | 20℃ Volume resistivity | Ω.m | GB/T1410 | 7.6*1011 | 8.3*1012 | 7.9*1010 |

12 | Shore hardness SHA |

| GB2411 | 92 | 94 | 92 |

13 | Vertical burning test |

| GB4609 | FV0 | FV0 | / |

14 | Horizontal combustion test |

| GB2408 | PASS | PASS | PASS |

LR-5001A LSZH FRPO

CPR D

No. | Items | Unit | LR5001A Typical value |

1 | Density | g/cm3 | 1.45 |

2 | Tensile Strength | MPa | 12.2 |

3 | Elongation at break | % | 174 |

4 | Thermal aging properties | ℃×H | 110×168 |

4.1 | Tensile Strength | % | 11.5 |

4.2 | Change in tensile strength | % | -5 |

4.3 | Elongation at break | % | 155 |

4.4 | Change in elongation at break | % | -13 |

5 | Resistant to environmental stress cracking, FO Number of failures/tests | H | 120 |

6 | Thermal deformation(90℃×1kg) | % | 15 |

7 | Low temperature embrittlement temperature (-40) Number of failures | One | 0/30 |

8 | Oxygen Index | % | 45 |

9 | Maximum smoke density Dm (no flame method) | 245 | |

10 | Hydrogen halide gas content | 0 | |

11 | Burning gas PH | 5.0 | |

12 | Combustion gas conductivity | μs/cm | 6 |

13 | Volume resistivity at 20°C | Ω·m | 5.4×1011 |

14 | Shore hardness | SHA(D) | 52 |

15 | Dielectric strength | MV/m | 24 |

16 | Toxicity index | 3 |

LR-5002NY LSZH FRPO

No. | Items | Unit | Test Methods | LR5002 Typical value | |||

High speed | 55D | Ointment | -H | ||||

1 | Density | g/cm3 | GB/T1033.1 | 1.44 | 1.45 | 1.46 | 1.47 |

2 | Tensile Strength | MPa | GB1040 | 15.1 | 15.6 | 14.6 | 13.4 |

Elongation at break | % |

| 165 | 161 | 168 | 166 | |

3 | Air heat aging | ℃×h | GB/T2951.2 | 100×168 | |||

Tensile strength retention | % | GB/T2951.1 | 108 | 108 | 110 | 106 | |

Elongation at break retention | % | 83 | 83 | 82 | 82 | ||

4 | Resistant to environmental stress cracking | F0--H | GB/T2951 | 180 | 180 | 175 | 175 |

个 | 0 | 0 | 0 | 0 | |||

5 | High temperature thermal deformation(90℃*1kg) | % | GB/T8815 | 10 | 8 | 13 | 14 |

6 | Low-temperature impact embrittlement(-40℃) |

| GB/T5470 | 0/30 | 0/30 | 0/30 | 0/30 |

7 | Oxygen Index | % | GB/T2406 | 33 | 34 | 33 | 33 |

8 | Smoke density | Flameless | GB/T8323 | 240 | 240 | 245 | 245 |

9 | Halogen acid gas content | mg/g | GB/T17650.1 | 0.2 | 0.2 | 0.2 | 0.2 |

10 | PH value |

| GB/T17650.2/ | 5.3 | 5.5 | 5.5 | 5.3 |

| Conductivity | μs/mm | 0.95 | 0.70 | 0.9 | 0.9 | |

11 | 20℃ Volume resistivity | Ω.m | GB/T1410 | 7.6*1012 | 8.3*1012 | 7.9*1012 | 5.5*1012 |

12 | Shore hardness SHD |

| GB2411 | 54.5 | 55.2 | 51.8 | 49 |

13 | Vertical burning test |

| GB4609 | FV0 | FV0 | FV0 | FV0 |

14 | Horizontal combustion test |

| GB2408 | PASS | PASS | PASS | PASS |

LR-5002H LSZH FRPO for 5G Opticalfiber Cable sheath

No. | Pilot projects | Unit | Test Methods | LR5002 Typical value | |||

High speed | 55D | Ointment | -H | ||||

1 | Density | g/cm3 | GB/T1033.1 | 1.44 | 1.45 | 1.46 | 1.47 |

2 | Tensile Strength | MPa | GB1040 | 15.1 | 15.6 | 14.6 | 13.4 |

Elongation at break | % |

| 165 | 161 | 168 | 166 | |

3 | Air heat aging | ℃×h | GB/T2951.2 | 100×168 | |||

Tensile strength retention | % | GB/T2951.1 | 108 | 108 | 110 | 106 | |

Elongation at break retention | % | 83 | 83 | 82 | 82 | ||

4 | Resistant to environmental stress cracking | F0--H | GB/T2951 | 180 | 180 | 175 | 175 |

One | 0 | 0 | 0 | 0 | |||

5 | High temperature thermal deformation (90℃*1kg) | % | GB/T8815 | 10 | 8 | 13 | 14 |

6 | Low-temperature impact embrittlement(-40℃) |

| GB/T5470 | 0/30 | 0/30 | 0/30 | 0/30 |

7 | Oxygen Index | % | GB/T2406 | 33 | 34 | 33 | 33 |

8 | Smoke density | Flameless | GB/T8323 | 240 | 240 | 245 | 245 |

9 | Halogen acid gas content | mg/g | GB/T17650.1 | 0.2 | 0.2 | 0.2 | 0.2 |

10 | PH value |

| GB/T17650.2/ | 5.3 | 5.5 | 5.5 | 5.3 |

| Conductivity | μs/mm | 0.95 | 0.70 | 0.9 | 0.9 | |

11 | 20℃ Volume resistivity | Ω.m | GB/T1410 | 7.6*1012 | 8.3*1012 | 7.9*1012 | 5.5*1012 |

12 | Shore hardness SHD |

| GB2411 | 54.5 | 55.2 | 51.8 | 49 |

13 | Vertical burning test |

| GB4609 | FV0 | FV0 | FV0 | FV0 |

14 | Horizontal combustion test |

| GB2408 | PASS | PASS | PASS | PASS |

Note 1: The data in the table are alltypical values and should not be regarded as a specification limit or designbasis for a separate reference.

Note 2: The environmental protection requirements are in line with the EU RoHSdirective and the latest REACH directive 173 substances of very high concern.